How Does Material Selection Affect zfcera Ceramic Plates Performance?

3 minutes, 24 seconds

-1 View 0 Comments 0 Likes 0 Reviews

3 minutes, 24 seconds

-1 View 0 Comments 0 Likes 0 Reviews

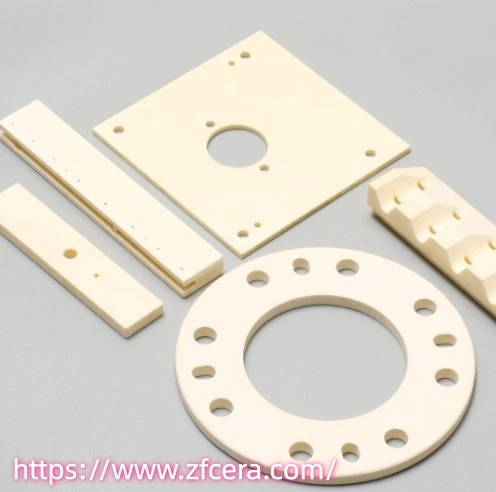

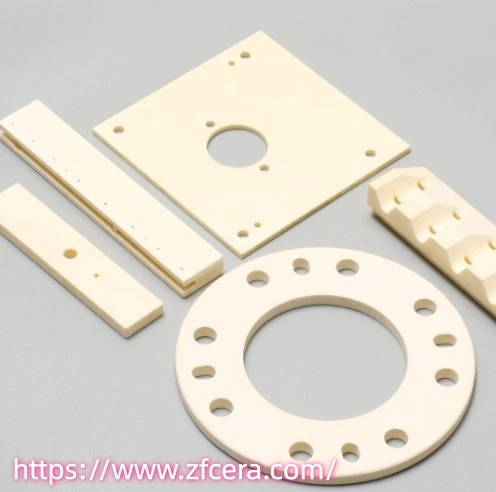

Ceramic Plates designed by zfcera blend artistic elegance with practical durability, transforming everyday tableware and industrial applications alike. Their advanced compositions provide resilience against mechanical stress while maintaining aesthetic appeal. Each plate embodies meticulous craftsmanship, delivering a balance of form and function that appeals to designers, manufacturers, and engineers seeking versatile materials.

In modern kitchens and dining spaces, decorative ceramic plates play a pivotal role. Beyond visual presentation, they withstand frequent temperature changes and resist surface wear, ensuring long-term usability. Innovative glazing techniques offer color stability, surface smoothness, and hygienic properties without compromising the underlying material's strength. Their versatility allows seamless integration into both contemporary and traditional dining settings.

Industrial environments benefit equally from structural ceramic plates. These components endure abrasive conditions, high pressures, and chemical exposure, outperforming conventional alternatives. Applications range from machinery liners to protective barriers in chemical and manufacturing facilities. Engineers can leverage these plates to enhance operational reliability while minimizing maintenance demands, combining mechanical robustness with functional efficiency.

Production of these plates requires precision engineering. Controlled firing, exacting material selection, and surface treatments guarantee consistent quality across batches. Each plate undergoes rigorous inspection for density, hardness, and dimensional stability, ensuring suitability for high-stress industrial applications or high-end consumer products. Advanced tooling allows designers to customize thickness, shape, and surface texture, meeting exacting project specifications.

The interplay between aesthetics and performance defines zfcera's approach. Decorative plates maintain structural integrity even under thermal cycling or mechanical load, while industrial variants achieve unparalleled resilience in aggressive environments. Such dual-purpose applications illustrate the adaptability of ceramic technology and its capacity to bridge lifestyle and industry requirements.

Sustainability also guides production choices. The inherent inertness of ceramic materials ensures they remain stable and recyclable throughout their lifespan. Reduced replacement frequency translates into resource efficiency, and the long-term reliability of these plates contributes to lower energy consumption during operational use. Designers and engineers increasingly prioritize materials that align with eco-conscious goals.

Ceramic materials continue to evolve through innovation. Nanostructured composites and surface engineering enable enhanced scratch resistance, improved chemical tolerance, and customizable thermal behavior. These technological advances expand the potential for decorative and structural plates, enabling designers and industrial engineers to push the boundaries of functional applications without sacrificing visual or mechanical standards.

Ultimately, Ceramic Plates from zfcera represent a fusion of artistry, science, and durability. They provide elegant solutions for domestic environments while meeting demanding industrial specifications. For tailored applications and detailed information, explore www.zfcera.com

Share this page with your family and friends.