Related Blogs

How Shanghai MSD Ensures Ink Compatibility in Banner Materials

6 minutes, 15 seconds

-491 Views 0 Comments 0 Likes 0 Reviews

Across today’s global advertising landscape, materials must endure unpredictable weather, support vivid graphic expression, and remain cost-efficient, which is why the popularity of flexible substrates such as PVC Flex Banner continues to expand as brands, print houses, and distributors like Shanghai MSD International Trade Company search for dependable options that can manage both large-format pressure and long-term outdoor visibility. The material serves as a foundation for communication in environments that require not only visual clarity but also structural resilience, especially where wind, dust, and temperature extremes are part of daily conditions.

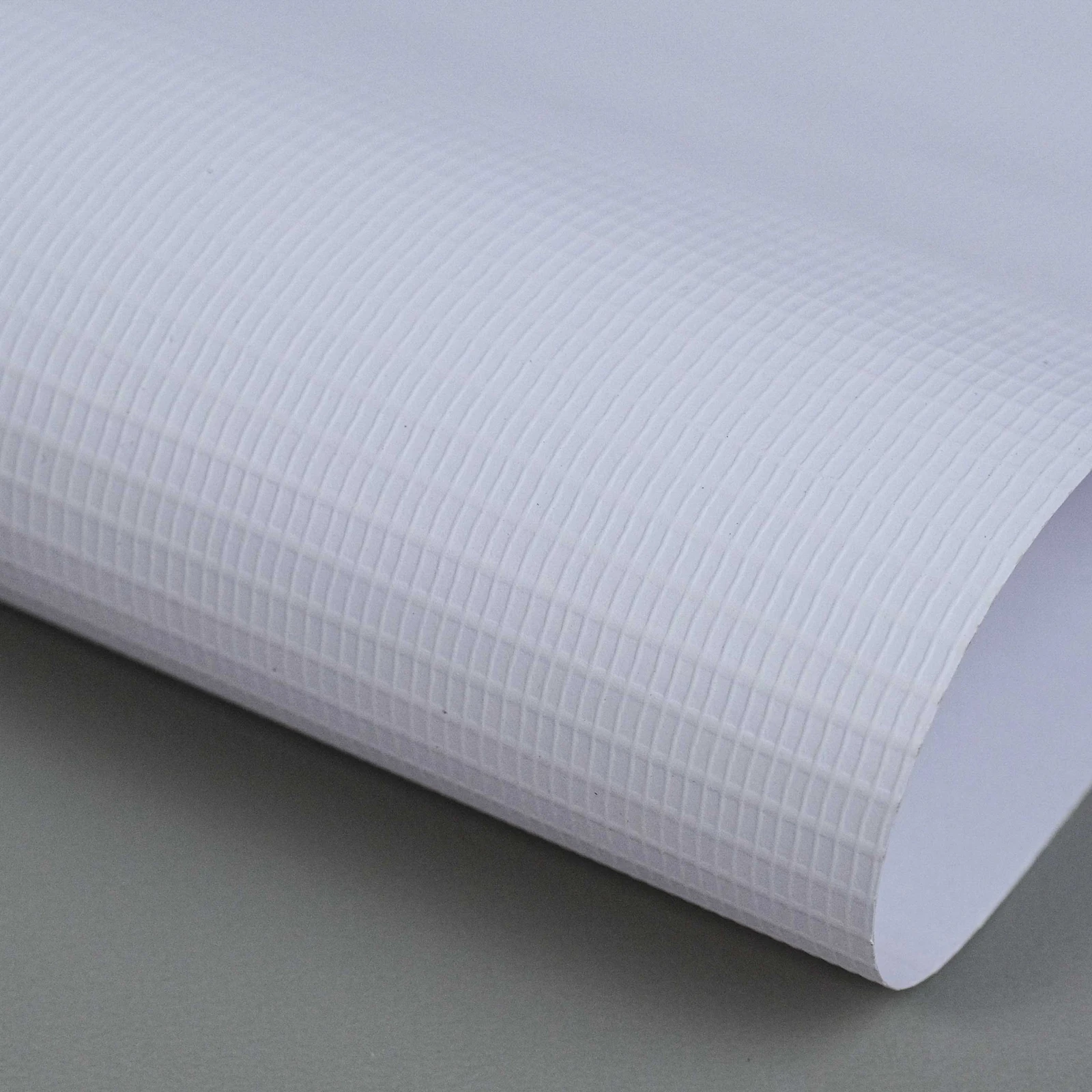

One of the defining elements behind this banner material is the integration of a reinforced mesh base. The fabric inside the composite helps control stretching forces, allowing the sheet to maintain flatness even when displayed across wide frames or suspended between structures. Manufacturers carefully select yarn thickness, weave patterns, and tension settings to produce a mesh that stays dimensionally stable during printing and installation. Without this internal fabric, the sheet would likely deform under heat, curl at the edges, or fail prematurely when subjected to repeated outdoor stress.

The polymer layers surrounding the mesh require equal attention. Formulators balance stabilizers, plasticizers, and processing aids to create a smooth printable surface while preserving elasticity. Too much softness can lead to material sagging, while overly rigid compositions may crack during cold-weather handling. Production lines must maintain uniform coating thickness to avoid issues such as uneven ink absorption, gloss variation, or local stiffness. Shanghai MSD emphasizes rigorous monitoring at this stage to ensure consistency, which ultimately affects print shops’ ability to reproduce detailed graphics without banding or color distortion.

Processing pathways differ according to the intended application. Laminated alternatives offer lightweight performance for short-term promotional cycles, making them suitable for seasonal campaigns or interior displays where handling convenience is a priority. Coated variants, produced by depositing molten polymer directly into the mesh, provide greater mechanical strength and better long-term durability. These are often used in large building wraps, roadside billboards, and long-span signage requiring stable behavior under continuous wind load. Each route contributes distinct tactile qualities, allowing buyers to choose an option that aligns with installation environment, print method, and expected life span.

Quality assurance governs whether the final material is truly reliable. Tensile and tear resistance tests simulate stress concentrated around grommets and edge reinforcements. Dimensional stability tests measure shrink, expansion, and distortion over cycles of heat, humidity, and tension. Surface wettability assessments ensure that ink anchoring remains predictable across different printing systems. When banners fail prematurely, it often traces back to insufficient control over these characteristics, highlighting the importance of multi-stage testing in production environments.

The printability of the substrate largely defines its commercial value. High-resolution output requires a surface free from micro-defects that could divert or absorb ink unevenly. Substrates must accept solvent, eco-solvent, UV, or latex systems without interfering with curing or color development. Superior surfaces offer minimized dot gain, crisp edges, and deep saturation, all essential for compelling campaigns. Additives within the polymer also contribute to fade resistance, helping maintain vibrant tones during prolonged sunlight exposure.

Environmental performance remains a main driver behind its widespread adoption. When installed outdoors, banners endure wind-flutter cycles, rain impact, pollutant deposition, and thermal expansion. Materials must therefore retain flexibility even after prolonged UV exposure or thermal cycling. Anti-fungal components prevent biological growth, especially in tropical or rainy regions. Moisture resistance ensures that printed areas do not delaminate or blister during unpredictable weather. These durability traits make the substrate reliable for long-term signage, construction coverings, event branding, and transportable promotional displays.

The material’s versatility creates opportunities in fields beyond traditional advertising. Retailers use it for indoor hanging displays that require lightweight handling. Event planners appreciate its ability to be rolled, transported, and installed quickly. Large venues rely on it for directional information, stage backdrops, and temporary decorative features. Construction companies adopt it for perimeter fencing graphics, using the material’s strength to form a protective barrier while delivering visual messaging. Its adaptability to finishing techniques such as welding, sewing, and eyelet reinforcement expands its utility across different installation conditions.

As industries seek substrates that combine flexibility, smooth print surfaces, and long-term resilience, companies like Shanghai MSD play an essential role in guiding material selection and ensuring dependable quality in global markets. Their product range and supply capabilities continue to support distributors and print professionals who depend on consistent performance. Additional information can be found through their product listings at: https://www.shanghaimsd.com/product .

Shanghai MSD PVC Flex Banner ink compatibility image clarity outdoor durability

Photos

Share this page with your family and friends.